What is Osmo wood finish?

Osmo wood finish is a natural finish made from vegetable oils (sunflower oil, soya bean oil, thistle oil and linseed oil), and natural waxes (carnauba wax and candela wax). Osmo has a full line of both interior and exterior finishes along with maintenance products. Let's explore the Osmo interior product line.

How does Osmo Interior wood finish work?

Osmo works by penetrating into the surface of the wood and then leaving a breathable wax surface. The natural vegetable oils penetrate the wood which keeps the wood moist and elastic, while the waxes dry to create a durable surface. Because Osmo is a penetrating wood finish it will not crack or peel. To refinish the surface you can give it a good clean and reapply more finish without having to sand down to raw wood.

How to apply Osmo?

Preparing your surface is always an important step in applying wood finishes. Osmo suggests that you sand your wood to 150-220 grit. It is not suggested to sand any higher as this will close the pores of the wood and prevent the finish from penetrating.

It is recommended to have 60g of finish per sq meter on you project. We have lots of application tools for you to choose from. See the image bellow to decide on out preferred method and how many coats you will need.

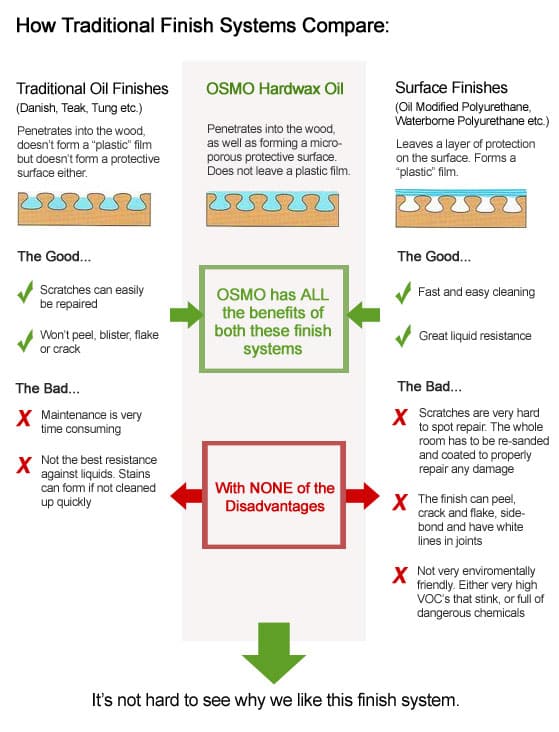

What is the difference between Osmo and other wood finishes?

Traditional oil finishes like Danish oil or Tung oil are also penetrating oil products that protect the wood from within. However without the wax component they do not offer the same protection as the Osmo product. They can be harder to maintain.

Traditional Lacquer or Polyurethane products are film forming and protect your wood from the outside. These finishes tend to have more of a plastic feel to them. They are easy to maintain but difficult to repair, as generally you would have to remove all the finish before refinishing the project.

Osmo Hardwax Oil wood finish penetrates the wood and protects from within and also forms a protective microporous surface protecting from the outside as well. It is resistant to water and abrasion, is easy to maintain and easy to repair and refinish. You can spot sand and refinish without taking all the finish off. It will not crack, blister or peel.

Osmo Interior Finish Line Up

Osmo has a large selection of interior products to chose from. The following includes their different features.

Clear finish and Top Coats

Osmo Top Oil & Chopping Block Oil

This is Osmo's line of food safe finishes. These can be used on kitchen work tops, cutting and serving boards, wooden bowls and anywhere that will come in direct contact with food. These have been independently tested and are certified by Euro-norm 1186 5/14.

Three options for Top Oil are available:

- Clear which provides a satin finish

- Natural which has a bit of white pigment leaving the wood looking unfinished (does not work well on woods like walnut)

- Acacia is a deep medium to dark brown

Chopping Block Oil is very similar but is a matte finish and only comes in clear.

Polyx Oil

Polyx Oil is our go-to product! It is hard wearing and can be used on most interior projects. We have 4 options available:

- Satin 3043

- Matte 3031

- Gloss 3011

- Raw 3051 which has a bit of white pigment leaving wood looking unfinished

Wood Wax Extra Thin 1101

We suggest Extra Thin for exotic woods or as the first coat on epoxy table.

Wood Wax Clear 3101

Wood Wax Clear would be used in places where you just want to do one coat. Ceilings, wall paneling and other decorative wood features that do not need abrasion resistance.

2K Wood Oil

Osmo 2K is a faster curing one coat system. They do have a clear option in this line. This is a 2 part product so once you mix the hardener into the product you need to use it within 3-4 hours. This is a great product for flooring as it works best if you use a buffer.

Coloured Products

Osmo has 3 lines of stain and coloured finish.

Osmo Oil Stain

Osmo Oil Stain is just that; a stain. There are no waxes in this product and it is meant to colour your wood. The advantage to this product is that you can do multiple coats of the stain to build up to the colour you want. Take a look at this video to see different application methods and the results.

WoodWax and WoodWax Intensive is the colour line that we have had the longest here in Canada. Woodwax is versatile in that it can be a one coat finish in areas that do not get very much abrasion. Examples of this would be beams, wood wall paneling, and legs of a table. However, if you are doing a surface like a dining table or something you are sitting on, you should add a coat of the Polyx Oil to increase the durability.

WoodWax Intensive has a higher amount of pigment so the wood gets more pigment on in one coat and it can be done with 2 coats to come across as more of an opaque finish or with just one to give a transparent look.

Osmo 2K Colours

The Osmo 2K is the one coat product that can be buffed in with a drying agent. There is a full line up of colours along with the clear product to choose from. This product is really meant for one coat so it does not lend itself to building up colour. The big advantage to this product is that it speeds up the curing time from 2-3 weeks to 5-7 days.

To check out the full line of Osmo interior you can go here.